Company

Aitomatic

Position

Head of Product & Design

Year

2024

Market

APAC & US, B2B

Problem

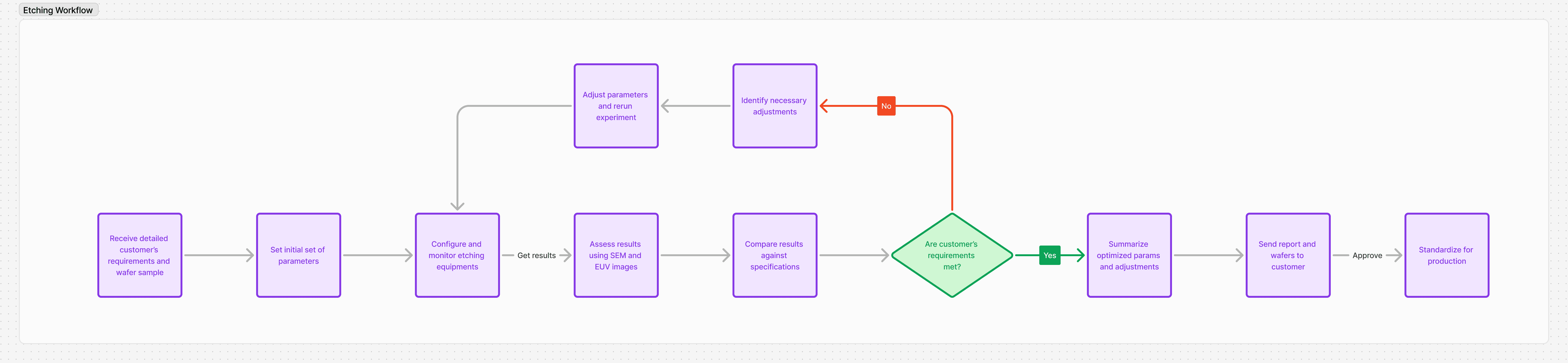

Semiconductor etching processes relied on trial and error, causing costly inefficiencies.

Solution

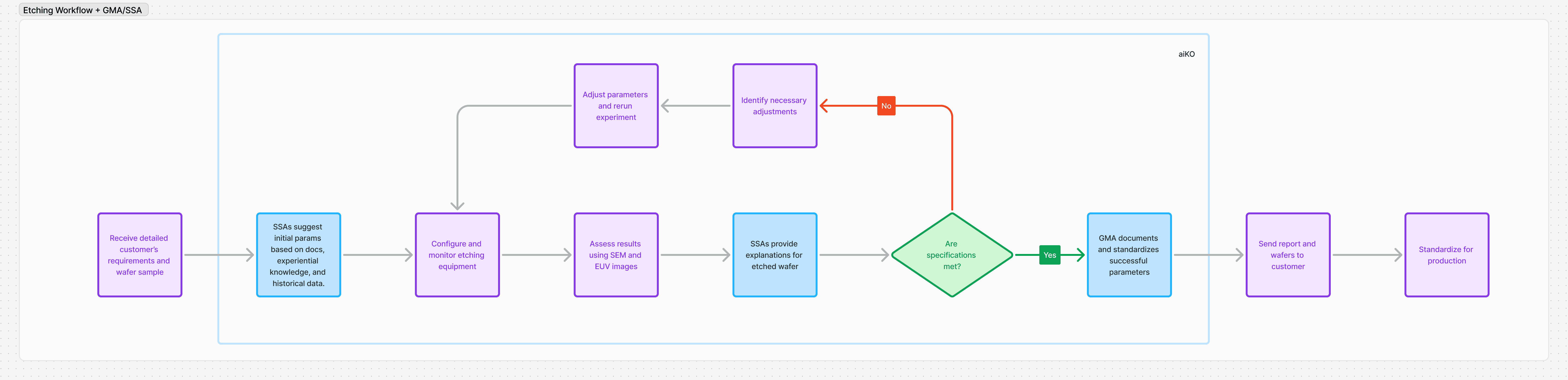

Led product vision and execution for GMA/SSA, a multi-agent AI system eliminating guesswork, restructuring workflows, and continuously learning engineers' knowledge.

Impact

•

Setup time dropped 30%, speeding up production

•

Saved $20K per etching cycle

•

$10M+ potential savings per year

Problem

Semiconductor etching demands absolute precision, but even at a company like Tokyo Electron (TEL), process engineers still relied on trial and error. They had to interpret complex specs and manually set key parameters (gas mixtures, droplet sizes, temperature) without a shared system of record. Mistakes were costly. A wrong parameter adjustment could delay production or waste entire wafer batches, often losing $10K to $20K per cycle.

TEL came to us looking for something they didn’t have: a system that could help engineers reach the right decisions faster, standardize what worked, and keep improving over time.

Design principles

Based on conversations with TEL engineers and the specific needs to etching efficiency, I established principles that guided our product decisions:

Engineers must understand AI recommendations clearly.

Human experts remain at the center of decisions, with AI augmenting their expertise.

AI must continually learn and permanently store expert knowledge to scale confidently.

Design process

I led product vision and design execution end to end: from research to systems thinking, workflows, UI, and validation. I worked closely with TEL engineers across multiple sessions to understand their language, mental models, and where exactly breakdowns were happening.

Difficulty interpreting parameters from customer specifications.

Misinterpretations of SEM and EUV images leading to incorrect parameters.

Inconsistent standardization of successful parameters for future use.

What we built

Impact

Before adopting GMA/SSA, TEL engineers oftentimes struggled through costly guessing. After implementation, their optimization time improved by 30%, leading to faster production. Their cycle saving is $20K, with potential for $10M+ per year across TEL.

Most importantly, TEL engineers described GMA/SSA as "the expert team that never forgets, explains every single step, and continuously improves our workflows."