Knowledge Base in aiKO

Preserve engineering know-how at scale

Company

Aitomatic

Position

Head of Product & Design

Year

2024

Market

APAC & US, B2B

Problem

In industrial manufacturing, engineering teams depend on senior engineers’ specialized knowledge built over years of real-world experience. When experts leave the organization, solutions vanish with them, impacting efficiency and quality.

Engineers required context-rich insights integrated with live machine stats, so the knowledge outlives personnel changes and businesses can stabilize their production quality.

Design principles

I defined clear principles to guide building the aiKO Knowledge Base: designing a knowledge system that mirrors how senior engineers naturally reason and troubleshoot.

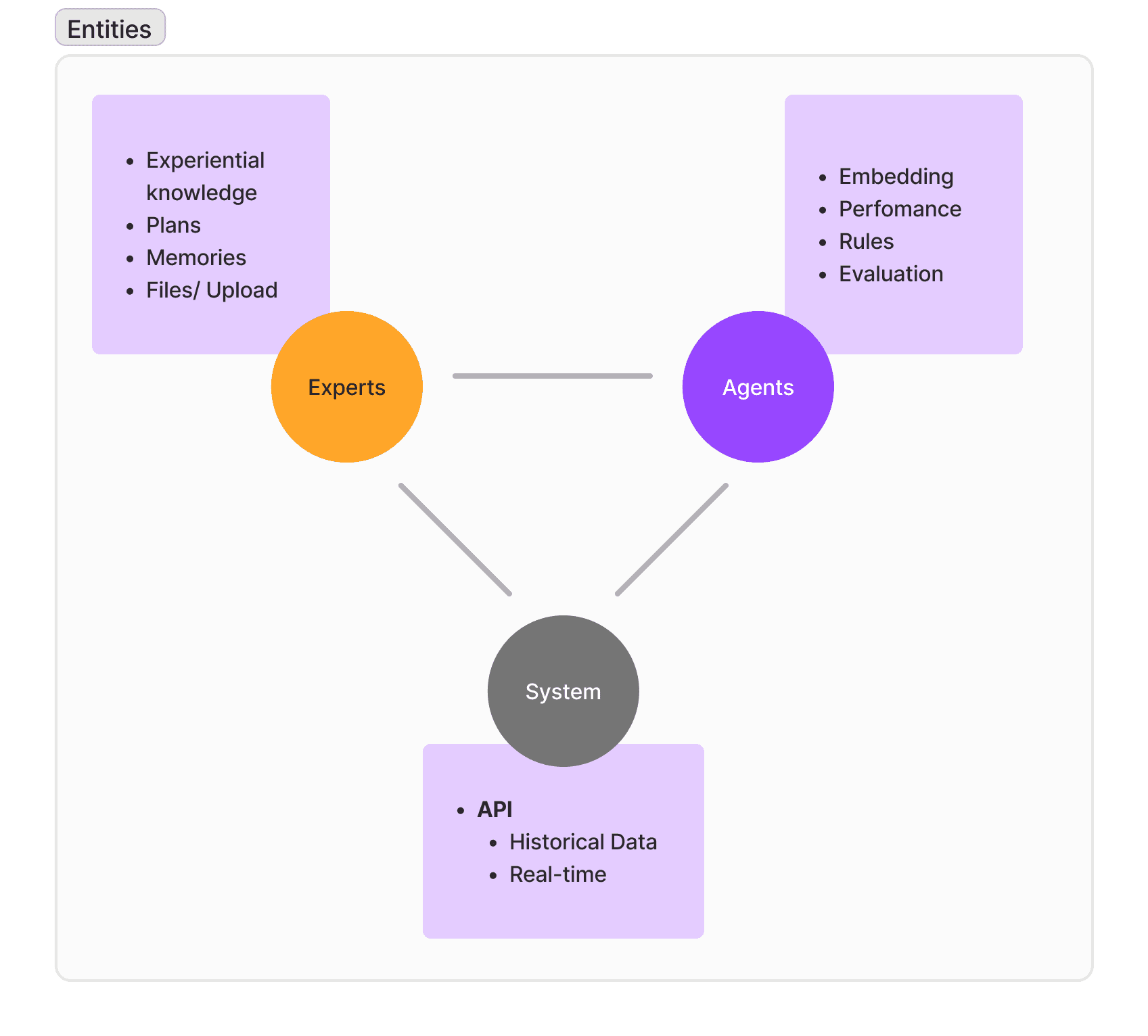

Human thinking doesn't store isolated data points. Engineers link concepts, organize ideas contextually, and apply relevant insights based on scenarios. Our knowledge base must also be structured around hierarchies, relationships, and deep data integrations.

Design process

I led a small interdisciplinary team: two frontend, two backend developers and one designer. We conducted in-depth user research and technical scoping sessions with engineers at PepsiCo, RHI Magnesita, and Tokyo Electron.

From user research, we learned how engineers searched for answers, solved troubleshooting issues, and utilised system data to validate the fixes. We embedded real-time machine sensor data and data from websites into our knowledge base. The goal was making data actionable in agents' answers.

What we build

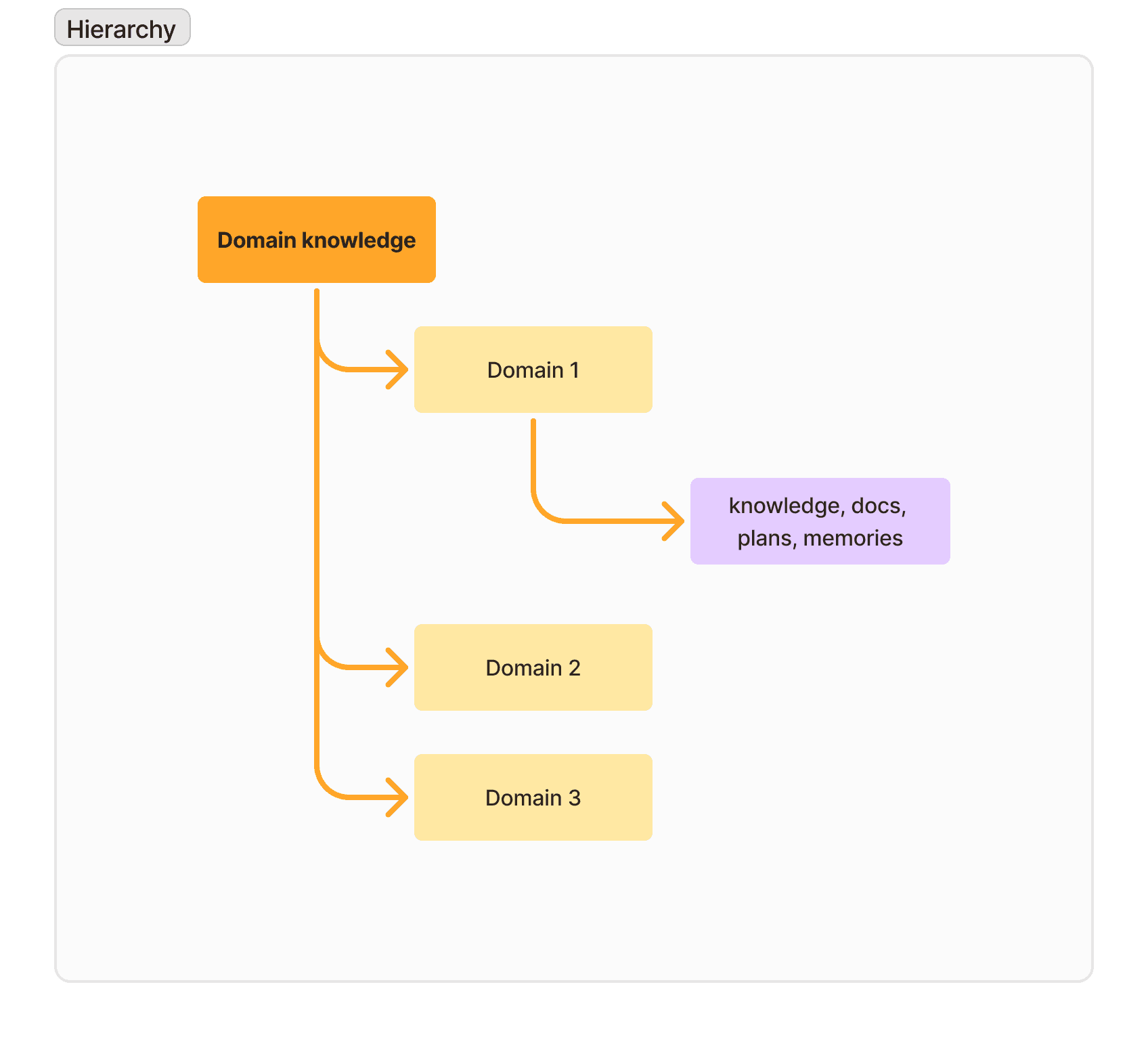

The Knowledge Base provided an contextual interface for capturing, accessing, and applying specialized engineering know-how. Experts documented knowledge, linking related concepts and troubleshooting insights through hierarchical connections.

Our AI integration fully captured both explicit documents and implicit expert reasoning, combined with real-time live sensor data (pressure sensors, temperature readings, statuses).

Through advanced semantic embedding, aiKO provided fully multimodal reasoning: integrating PDFs, system events, past issue history, sensor readings, and troubleshooting logs, driving richer contextual outputs and evidence-backed reasoning.

Impact

The Knowledge Base was projected to deliver performance gains like cut troubleshooting time by 25% and reduced new engineer onboarding time by 40%.

Early customers, including PepsiCo, RHI Magnesita, and Tokyo Electron, initiated integration deployments. aiKO with the Knowledge Base transformed how engineering expertise was shared across teams, and applied at operational moments in production environments.